Bein' a cheap bastid myself, I've tried to dye my own purfling, using curly maple veneer I had cut into purfling strips using a pasta maker.

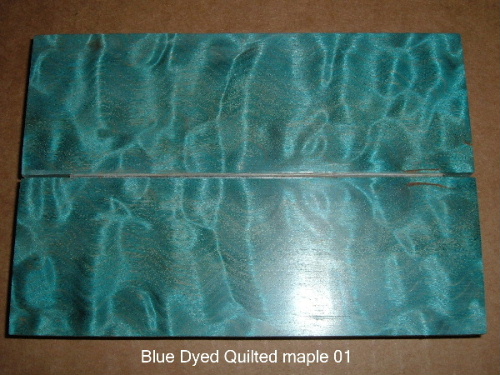

I tried using a pressure cooker with Rit fabric dyes. Well, actually only with one color -- blue. I discovered that Rit's blue dye is sensitive to the higher heat a pressure cooker generates, and breaks down to a greenish-brown color. Yuck.

So, I tried cooking dyes -- blue, green, and red -- in the cooker with the lid off, keeping the temp regulated at 150 degrees. I cooked each batch for several hours. Even after this, I found that I was getting minimal penetration with purfling that is only about 0.025" thick.

I'm reasonably sure that a pressure cooker would work, but the dyes have to be able to withstand a higher temp than say 250F or so.

Also, still on the subject of purfling, I install a 1mm wide (~0.040") single purfling line on my sides and backs. I've been using curly maple for this too. Sometimes, though, I get a bit of bleedover from the surrounding back/side wood (and binding) that will stain the "curls" in the maple. A light wash coat of shellac, carefully applied with a clean muneca, can limit this.

I preglue the purfling to the binding before bending. I find that, since sometimes binding needs to be lightly soaked, Titebond II works better for this because of its water resistant properties.

Best,

Michael

|

)

)